![]()

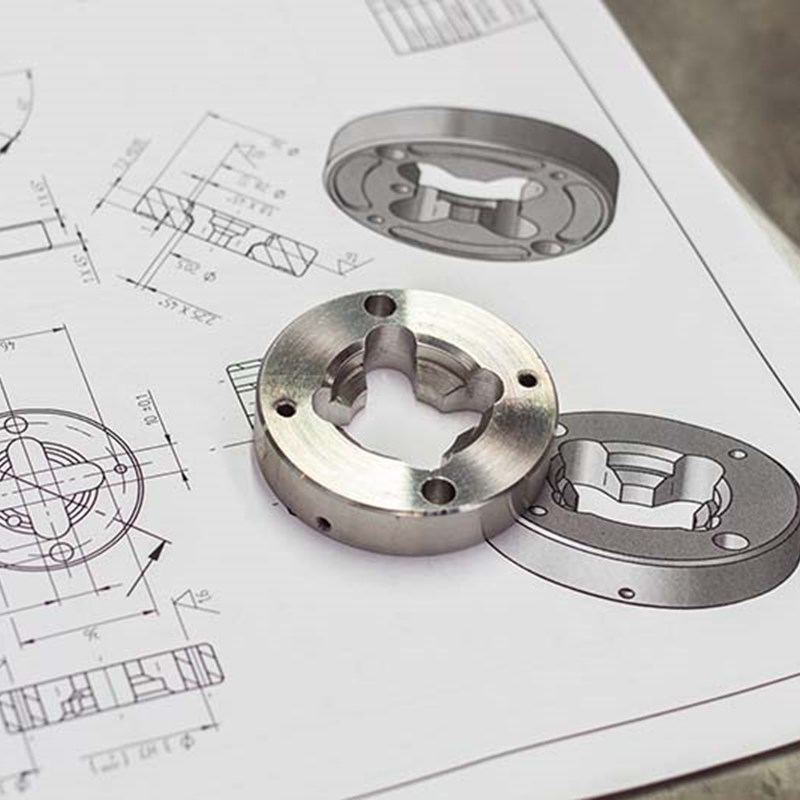

If you don't have an engineer on staff, we can assist you every step of the way.

We understand how crucial it is to prepare a precise print layout since even an error as small as one-thousandths of an inch off will result in a rejected part. If the engineer does not get the prints right from the start, there are guaranteed problems throughout the production.

The key to a quality end-product is thorough analysis and precise calculations during the development of your product prints, and with a 99.9% success rate for producing accurate prints, our team of skilled engineers are qualified to deliver a quality end-product.